If you want to create a product that has got to be manufactured, its good to

keep the manufacturing process in mind while designing your product.

Today we are going to look at product design for Injection moulded products.

The first thing you must be aware of is that as most materials, plastics

expend when heated. Because you must heat plastics to get it in a mould, the product will shrink

when cooling down and will be smaller than your mould. We counter this with a shrinkage

factor varying between 0.3% to more than 2.5%.

There are lists available with shrinkage factors of the most common

plastics.

Because of this shrinking, products will come loose from the outer edges an

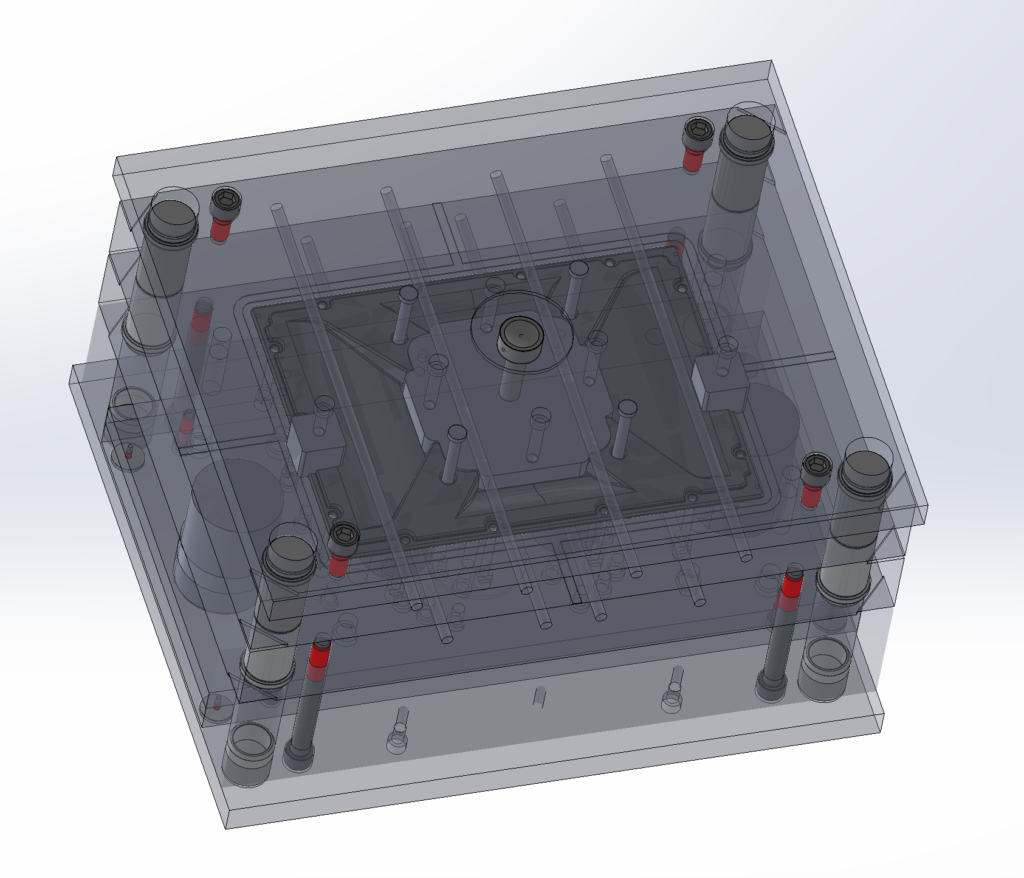

will stick to the inner edges of the mould. Before we make the mould whe have to make sure the product sticks to the side we want.

This will most likely will be the B-side (the moving side) of the mould.

This is the side where we place our ejectors, the pins that eject the

product

When designing a product that has to be moulded, try to avoid undercuts (you

will need slides) or straight surfaces. They will make your mould way more expensive than a simple product.

To be continued

more will follow